3D printing, once considered a technology of the future, is now an integral part of everyday life. From manufacturing to healthcare, and from education to home use, 3D printing gadgets are revolutionizing various industries and improving our day-to-day activities. In this article, we will explore how these innovative gadgets are transforming different sectors, enabling advancements that were once deemed impossible.

What is 3D Printing?

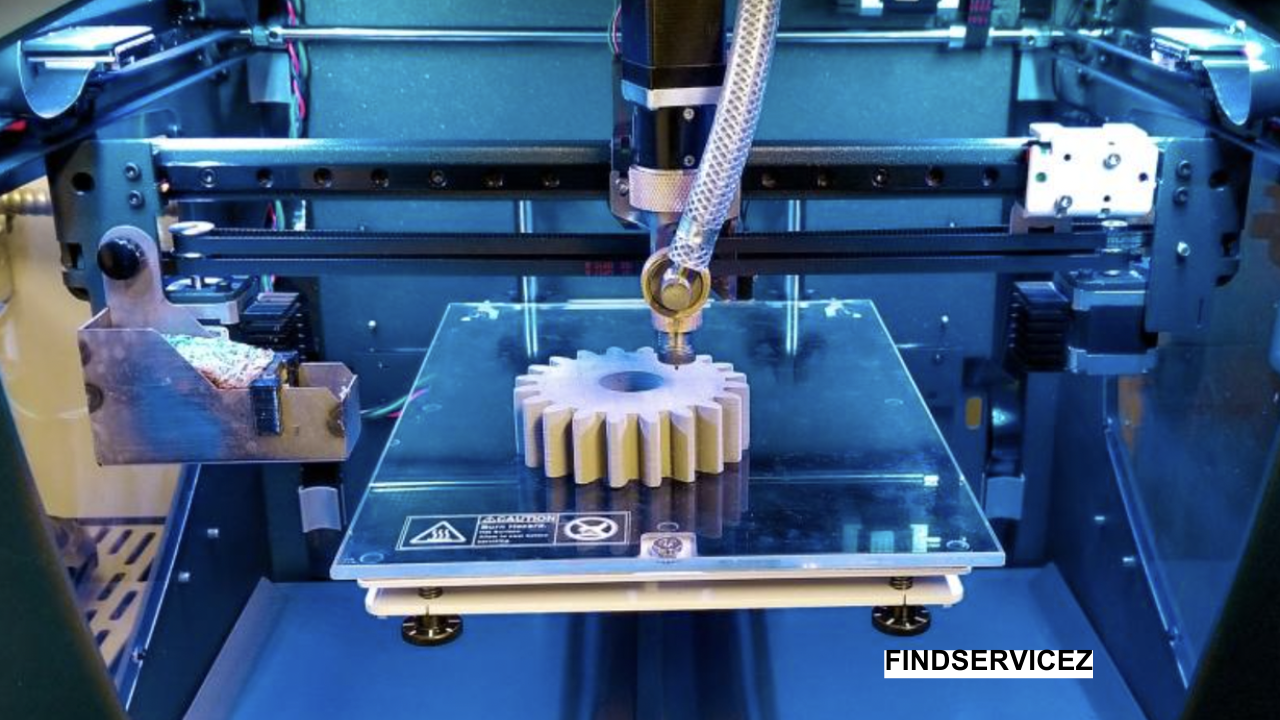

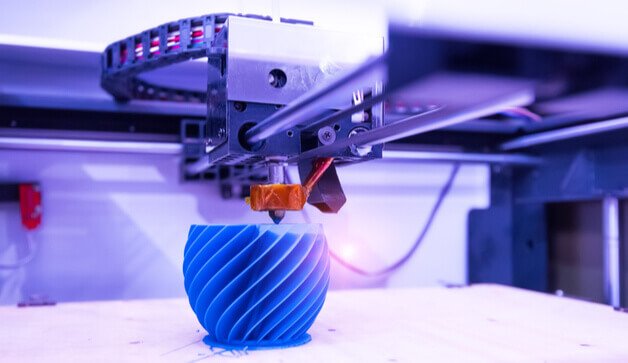

At its core, 3D printing is an additive manufacturing process that involves creating objects by layering material based on a digital model. Unlike traditional manufacturing methods, which often require cutting, drilling, or molding materials, 3D printing builds objects layer by layer, offering greater flexibility, customization, and efficiency. The process is versatile, with applications ranging from producing small-scale prototypes to manufacturing complex, functional items.

The Rise of 3D Printing Gadgets

Over the past decade, the popularity of 3D printing gadgets has surged, especially as the technology has become more affordable and accessible to consumers. Today, 3D printers are found in homes, offices, and schools, and many industries are embracing the potential of 3D printing for faster and more cost-effective production. The ability to create products on demand, with intricate designs and customized features, is reshaping how we interact with technology and the world around us.

Let’s dive into the specific ways in which 3D printing gadgets are transforming everyday life.

1. Revolutionizing Healthcare: Customized Medical Devices

One of the most significant impacts of 3D printing is its role in revolutionizing healthcare. Customized medical devices, such as prosthetics, implants, and hearing aids, are now being manufactured with precision, speed, and affordability. 3D printing allows healthcare professionals to produce patient-specific devices tailored to the unique anatomy of an individual.

The Most Anticipated Tech Gadgets of 2027: A Glimpse into the Future of Technology

- Prosthetics: Traditional prosthetics can be expensive and may not fit well, causing discomfort or requiring frequent adjustments. 3D printing has enabled the creation of low-cost, personalized prosthetic limbs, improving mobility and quality of life for patients. These prosthetics can be designed to fit the patient’s specific measurements and preferences, offering a level of customization that was previously unimaginable.

- Implants: 3D printing also plays a crucial role in producing implants for surgeries, such as joint replacements and dental implants. These implants can be made to precisely match a patient’s bone structure, reducing the risk of complications and improving recovery times.

- Organ Models: Surgeons are using 3D-printed models of organs and tissues to plan complex surgeries. By printing a physical model based on a patient’s MRI or CT scan, doctors can visualize the exact location and shape of tumors, arteries, or fractures before operating. This technology enhances surgical precision and helps reduce the time spent in the operating room.

2. Empowering Education: Hands-On Learning Experiences

In the education sector, 3D printing gadgets are transforming how students learn by offering interactive and hands-on experiences that promote creativity and problem-solving. Students can now create models, prototypes, and interactive visualizations in subjects ranging from engineering to history.

- Prototyping and Design: 3D printing encourages students to think outside the box by allowing them to create their own prototypes and models. In design and engineering programs, students can bring their ideas to life by printing tangible versions of their projects, helping them to better understand concepts and principles in a practical way. These gadgets enable a deeper understanding of subjects by offering a physical representation of abstract concepts.

- Interactive Learning: In subjects like biology or geography, 3D-printed models of cells, maps, or historical artifacts enhance learning by giving students a tactile, real-world connection to what they are studying. Imagine studying the solar system by holding a 3D-printed model of each planet or understanding human anatomy through detailed 3D-printed body parts.

- Special Needs Education: 3D printing is especially beneficial for students with special needs. Custom tools, such as specialized grips for pens or individualized learning aids, can be created to support students’ unique needs, helping them succeed in their education and daily lives.

3. Changing Manufacturing and Retail: Faster, More Efficient Production

3D printing is transforming the manufacturing and retail industries by enabling faster production times and reducing costs. In traditional manufacturing, large quantities of products are often mass-produced in a factory, which can be expensive and time-consuming. With 3D printing, businesses can produce products on-demand, reducing inventory costs and allowing for greater customization.

- Custom Products: Retailers are using 3D printing to create bespoke products for customers. Whether it’s a custom phone case, personalized jewelry, or tailored home décor, 3D printing allows consumers to design and print unique items that reflect their personal style. These gadgets make it easier for individuals to create the exact product they want, without the need to wait for mass production or deal with limited choices.

- Rapid Prototyping: In industries like automotive and aerospace, 3D printing is used for rapid prototyping. Engineers can create quick prototypes of parts or tools, test them for functionality, and then refine the design before committing to large-scale production. This approach speeds up the innovation process, allowing companies to bring products to market faster.

- Sustainability: 3D printing can also contribute to more sustainable manufacturing practices. Traditional production processes often lead to waste as excess materials are cut away or discarded. 3D printing, however, uses only the material required to create an object, reducing waste and making it more environmentally friendly. Additionally, 3D printing allows for the use of recycled materials, further contributing to sustainability efforts.

4. Improving Home Life: Everyday Gadgets and Personalized Tools

At home, 3D printing is making it easier for individuals to create everyday gadgets and tools that are tailored to their specific needs. Whether it’s custom kitchen utensils, household decor, or even tools for DIY projects, 3D printing enables homeowners to create items that would otherwise be difficult to find or expensive to buy.

- Home Improvement: DIY enthusiasts are using 3D printing to create custom tools and parts for home projects. Broken appliances can be repaired with 3D-printed replacement parts, saving money and reducing waste. Custom fixtures or fittings, such as light switch covers or unique drawer handles, can be easily designed and printed to fit specific dimensions.

- Personalized Products: Consumers can create products that are perfectly suited to their needs. For example, 3D printing allows people to make custom phone holders, organizers, or even ergonomic tools designed for comfort. This level of personalization enhances convenience and helps improve the quality of life at home.

- Decor and Furniture: 3D printing gadgets are also being used in home decor and furniture design. From intricate lamp designs to customized coffee tables, 3D printing allows homeowners to create unique pieces that match their aesthetic preferences and living spaces. This level of customization brings a new dimension to interior design.

5. Transforming the Food Industry: Innovative Culinary Creations

The food industry is another area where 3D printing is making waves. While it may seem unconventional, 3D printers are being used to create unique culinary creations, streamline food production, and even explore new ways to address food sustainability.

High-Tech Gadgets for Pet Owners in 2027: A Glimpse into the Future of Pet Care

- Food Printing: 3D-printed food allows chefs and food creators to experiment with intricate designs and new textures. With the use of edible materials, such as chocolate, dough, and even meats, chefs can create beautifully detailed and innovative dishes that would be difficult to achieve using traditional methods. This technology is being explored in high-end restaurants as well as in space food development for astronauts.

- Personalized Nutrition: As 3D printing technology advances, it could play a role in personalized nutrition. By printing food that meets the specific dietary needs of an individual, whether for health reasons or personal preferences, 3D printing offers the potential to transform how we approach meal planning and nutrition.

- Sustainability in Food Production: 3D printing can contribute to sustainable food production by reducing food waste and enabling more efficient production of ingredients. In the future, 3D-printed food could be used to address food security issues, as it allows for more precise control over ingredient usage and could help reduce global food shortages.

6. Innovating Transportation: 3D Printing for Vehicles and Parts

The transportation industry is also embracing 3D printing technology, particularly for creating components and parts for vehicles. Car manufacturers are utilizing 3D printing to create prototypes and custom components that can improve vehicle performance and reduce costs.

- Automotive Industry: 3D printing is used to create custom parts for vehicles, including lightweight components that can improve fuel efficiency and reduce overall vehicle weight. Additionally, car manufacturers are exploring 3D printing to create spare parts that are only printed when needed, eliminating the need for large inventories and reducing storage costs.

- Aerospace: In aerospace, 3D printing is enabling the production of complex parts that are both lightweight and durable, critical for reducing fuel consumption and ensuring safety. From engine parts to cockpit components, 3D printing is playing a crucial role in the development of next-generation aircraft.

- Space Exploration: 3D printing is even being explored for space missions. NASA has already experimented with 3D printing technologies to manufacture tools and components directly in space, reducing the need to send materials from Earth. This has the potential to revolutionize space exploration by making manufacturing more cost-effective and efficient.

The Future of 3D Printing Gadgets

The rapid development and widespread adoption of 3D printing gadgets are reshaping industries and enhancing our everyday lives in ways that were once unimaginable. From healthcare to education, manufacturing to food production, and home life to transportation, 3D printing is creating new possibilities and driving innovation. As the technology continues to evolve, we can expect even more breakthroughs that will further transform how we live, work, and interact with the world around us. The future of 3D printing is bright, and its impact on our daily lives will only continue to grow.